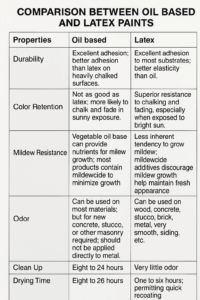

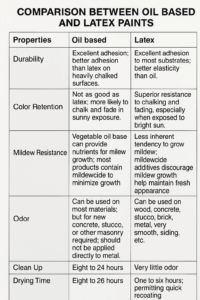

New and old paint formulations can lead to some confusion about the types of paints available and the differences between them.

There are two basic types of house paint commonly used for residential applications:

- “Latex” or water-based paint also called Acrylic Wall Paint

- “Oil” or “Alkyd” based paint

The term “Latex” is used by some paint companies to refer to their water-based paints. There is no natural latex in modern paints. The term “Oil-based” is used to refer to paints that have a linseed or Alkyd base. “Alkyd” is a synthetic oil base. These paints require a solvent such as mineral spirits for thinning and clean up. Oil or Alkyd based paints are almost exclusively considered “enamels” due to their hard durable, gloss or semi-gloss finish and are typically used for coating windows, doors, and woodwork trim. (Color will yellow or darken over time)

“Acrylic” or “Acrylic Latex” paint are water-based paints that contain “Acrylic” as the film forming binder ingredient. Neither contains any natural latex as an ingredient. “Acrylic” provides a non-yellowing durable finish with water cleanup.

“Acrylic enamel” or “Acrylic latex enamel” paint is water-based acrylic paint with a high durability rating. Neither contains any natural latex. Typically, these paints have a (non-yellowing) gloss or semi-gloss sheen for coating windows, doors, and woodwork trim with water cleanup.

Not all “latex” paints contain “acrylic”. Some contain different types of binders. Some film forming ingredients and fillers however “acrylic” is considered to be a superior type of ingredient and important part of high-quality paints.

Be sure to check the label for desired sheen and remember that the more shine the paint has the more it will show surface imperfection.

Choosing the Right Type of Paint

Many factors determine the type of paint that you should use on any given paint job, including the nature of the surface you want to paint and its condition, the age of the surface, and the type of paint previously used on the surface, if any. The other factors which are important today are waterproofing, crack protection, anti-dirt pick-up properties, crack bridging property, heat/thermal protection and non-fading colors.

Virtually all the paints that you might use around the home fall into two general categories: water-based latex paints; and solvent-based paints, which are commonly referred to as oil-based paints or “alkyds.”

These names refer to one of the major differences between the two types of coatings – most of the liquid portion of latex paints is water, while the liquid in oil-based paints consists of petroleum distillates and other organic solvents.

About 75% of all the paint that is sold today is of the latex variety. Do-it-yourselfers use an even higher percentage of this type of paint for both exterior and interior projects. But you should take nothing for granted when painting your home. You must consider the nature of your particular job to decide which type of paint is best for your application.

Characteristics of Latex Paints

Water-based latex paints have always been popular with do-it-yourselfers and professional painters because of their easy cleanup with plain soap and water. But today’s quality latex paints offer significant performance advantages as well.

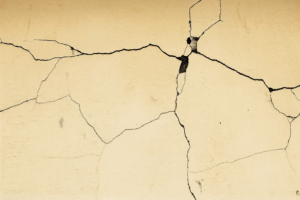

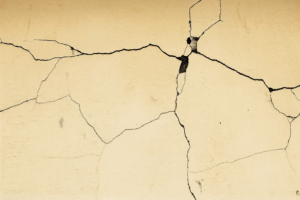

Compared to oil-based paints, top quality exterior latex paints have greater durability in the form of better color retention and chalk resistance, so they continue to look good for years. Since they do not tend to get brittle as oil-based paints do, they have better resistance to cracking. Latex paints also dry much faster than oil-based paints (typically in one to six hours), which allows you to quickly apply a second coat.

Quality latex paints that have “100% acrylic” binders are especially durable and highly flexible. They tend to adhere extremely well to a variety of exterior surfaces, which means they have greater resistance to troublesome paint failures like blistering, flaking and peeling, compared with other latex paints.

Walrus Paints offers a complete line of acrylic latex paints to suit different requirements of structure/building protection.

Selecting the Right Paint Sheen

Selecting the ideal sheen or gloss level for an interior or exterior paint job involves both aesthetic and practical considerations. From an aesthetic standpoint, a degree of sheen or gloss is useful in creating visual interest, particularly indoors. From a practical standpoint, the right sheen or gloss can help extend the life of the paint job, whether it is an interior or exterior application.

Walrus Paints products are available in a variety of sheens, so you will be sure to find one suitable for your painting project for interior surfaces. Non-reflective, so it conceals imperfections better than higher sheen paints. Stain removal may be more difficult than other sheens due to its more porous nature. Good choice for living rooms and bedrooms.

Interior Satin: Swarnakamal® Golden-Touch and Feather-Touch

Sheen is lower than a semi-gloss. Popular sheen, durable and elegant. Good for walls or trim in high-use areas such as hallways and bedrooms.

Eggshell: Swarnakamal® Magico

Superior quality acrylic paint that gives wall and other surfaces a low-reflective finish with elegant, natural luster like the subtle sheen of real eggshell. Sheen is higher than flat, slightly lower than a satin. Popular with designers as it is still relatively flat but offers washability. Good for walls or trim in high-use areas such as hallways.

Semi-Gloss, Exterior Satin: Swarnakamal® Elastocrete

Offers good stain resistance and is easy to clean. Washable and scrub able. Popular choice for bathrooms, kitchens, woodwork, and trim.

Gloss: Swarnakamal® Flareon

Toughest, most durable types of paint. Tends to highlight any surface characteristics. Excellent choice for trim and cabinets. Ideal for areas exposed to heavy traffic.

Walrus Paints provides you different choices of paints for exterior application.

i-Real and e-Real Cement Primers are ‘undercoat finishes’ which are suitable for new concrete, brickwork, asbestos, cement sheets, and plaster as the first coat. These fill the pores and gaps of wall surfaces, resulting in the best surface to get a good look after application of top coats. These also give water-repellent properties and adhesion on the surface with excellent interior/exterior bonding.

Reflection Standard/Gold/Platinum

Thanks to modern-day manufacturing technology and the high-quality materials in use, acrylic paint solutions today last much longer than ordinary paint products.

Waterproofed Paint: Reflection Flexcoat

Flexcoat is a new development in advanced acrylic paint with waterproofing properties and flexibility.

Elastomeric Wall Coating: Rainshield

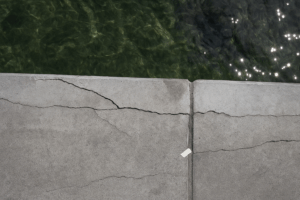

Elastomerics are applied at about five to ten times the thickness of traditional acrylic paints. This higher film build has some advantages, like minimizing the appearance of surface imperfections and offering waterproofing properties. Even though many elastomerics are said to “breathe”, their high film build results in a lower vapor transmission rate than traditional acrylics and thus tend to hold moisture in the wall. Water can enter a building at the perimeter of doors, windows, through-wall penetrations, and through cracks. Elastomerics will bridge hairline cracks if applied at their designated thickness. They are often sufficient to satisfy the many structural or settling cracks that appear.

SmartCoat / ArmourShield

These paints are designed to give self-cleaning properties as well as solar guard.

SmartCoat is a water-based high solid elastomeric coating utilizing the latest advances in acrylic technology. Highest quality 100% acrylic resins are combined with reinforcing laminar pigments, an effective biocide package and non-migrating fire retardant, resulting in superior durability, weatherproofing, ultraviolet resistance, algae/mildew resistance, and fire retardancy. SmartCoat is highly reflective, thermal insulating, permanently flexible, breathing membrane, allowing moisture vapor from the substrate or building interior to escape while remaining impervious to mass water penetration from the exterior. With inbuilt pigments, with photocatalytic properties, the surface remains clean.

Unique Features:

- 100% Acrylic-based coating available in textured or non-textured

- Hydrophobic; water-repellent

- Self-cleaning

- Pollution-reducing

- Long-term durability

- Photocatalytic; heat-reflective

- Superior flexibility, hardness, and solvent resistance

- Bridges substrate cracks up to 2mm

- Long-term crack resistance

- Superior freeze/thaw resistance

- Self-curing

- Very low shrinkage

- Non-toxic and environmentally friendly product

- Unique anti-fungus and anti-algae properties

- Superior exterior durability and UV light resistance

- High temperature stability

- Low temperature flexibility down to –15°C

High-Temperature Advantages

SmartCoat’s formulation of unique inorganic products allows increased insulation over the more conventional coatings now available.

Tensile Strength and Elongation

Thermal movement of a wall surface requires high tensile strength and elongation as well. The tolerance for movement of these coatings is essential due to the dynamic nature of a building substrate which expands and contracts due to climatic conditions and the shifting and settling of the foundation. These properties also give properly formulated elastomeric wall coatings the needed flexibility and elasticity to withstand impact from rain, wind, or other abuse without rupturing.

Water-Based PUD Technology: Superflex

Water-based polyurethane dispersions (PUDs) are a rapidly growing segment of the polyurethane (PU) coatings industry due to environmental legislations such as the Clean Air Act and also due to technological advances that made them an effective substitute for the solvent-based analogs. Water-based or waterborne PUDs have gained increasing importance in a range of applications, due in large part to properties such as adhesion to a range of substrates, resistance to chemicals, solvents and water, abrasion resistance, and flexibility. Water-based PUDs show very good mechanical and chemical properties and match the regulatory pressures for low volatile organic compound (VOC) containing raw paints. The continuous reduction in costs and the control of VOC emissions are increasing the use of water-based resins, motivating the development of PU dispersed in water. PU obtained from water-based PUDs have superior properties when compared with similar materials obtained from organic media. Water-based PUDs are used in many application areas to coat a wide range of substrates—for example, footwear adhesives, wood lacquers for flooring and furniture, leather finishing, plastic coatings, printing inks, and automotive base coats. Regarding the chemical nature of PU, the water-based PU are applied with higher solids content compared to the solvent-based PU, because their viscosity does not depend on the molecular weight of PU, as is the case for solvent-based PU. Thus, waterborne PUDs can be prepared at high solid contents with a molecular weight enough to form films with excellent performance resulting solely upon “physical drying.” This means that the film formation occurs by simple evaporation of water even at room temperature.

Hygiene Coatings

Polyurethane dispersions are used as the main or auxiliary binders in “Hygiene” coatings, where the coating’s main requirements of toughness and reasonable gloss, single-pack, water-based and low odor, easy cleanability, rapid drying, and fast property development are some of the more important properties. Food, pharmaceutical and personal hygiene plants, hospitals and nursing homes, hotels and restaurants, and anywhere there exists a requirement for clean, bacteria-resistant surfaces, these coatings provide the answer. “Hygiene Coatings” may be used on walls, ceilings, and floors, all based on specific types of polyurethane dispersions.

SUPERFLEX

SuperFlex is a water-based polyurethane dispersion-based coating for exterior and interior application, with advanced polymer technology. Being single component, it is brush or roller-applied waterproofing membrane. Unique properties of SuperFlex make it a unique product for new and old building construction.

Unique Features:

- Superior flexibility, hardness, and solvent resistance

- Bridges substrate cracks up to 2mm

- Long-term crack resistance

- Superior freeze/thaw resistance

- Self-curing

- Very low shrinkage

- Non-toxic and environmentally friendly product

- Easy application, single component, hence no mixing problems

- Designed with anti-fungus and anti-algae properties

For further details contact:

Multichem Industries Pvt. Ltd.

Phone No: +91 9619091025

E-mail: info@multichemgroup.net

Web: www.multichemgroup.net