Concrete has been used for construction in various ancient structures. An analysis of ancient Egyptian pyramids has shown that concrete may have been used in their construction, although the composition would have differed from modern concrete.

During the Roman Empire, Roman concrete was made from quicklime, pozzolana, and an aggregate of pumice. Its widespread use in many Roman structures—a key event in the history of architecture termed the Roman Architectural Revolution—freed Roman construction from the restrictions of stone and brick material and allowed for revolutionary new designs in terms of both structural complexity and dimension.

Modern structural concrete differs from Roman concrete in two important details. First, its mix consistency is fluid and homogeneous, allowing it to be poured into forms rather than requiring hand-layering together with the placement of aggregate, which, in Roman practice, often consisted of rubble. Second, integral reinforcing steel gives modern concrete assemblies great strength in tension, whereas Roman concrete could depend only upon the strength of the concrete bonding to resist tension.

The widespread use of concrete in many Roman structures has ensured that many survive to the present day. The Baths of Caracalla in Rome are just one example. Many Roman aqueducts and bridges have masonry cladding on a concrete core, as does the dome of the Pantheon. Some have stated that the secret of concrete was lost for 13 centuries until 1756, when the British engineer John Smeaton pioneered the use of hydraulic lime in concrete, using pebbles and powdered brick as aggregate. However, the Canal du Midi was built using concrete in 1670. Likewise, there are concrete structures in Finland that date back to the 16th century. Portland cement was first used in concrete in the early 1840s.

Today, the construction industry has become one of the vital constituents of the economy, contributing about 10% to the worldwide gross domestic product (GDP). The US, Europe, Japan, and Asia are the largest construction markets, controlling more than 70% of the construction market. China has the largest share, i.e., 44% of world cement production, and India accounts for a smaller size of world cement production.

In spite of this, India has a high level of potential for cement consumption because of the need for infrastructure development and other construction areas.

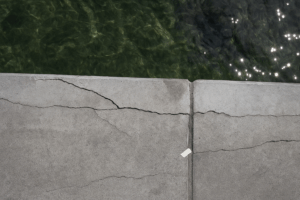

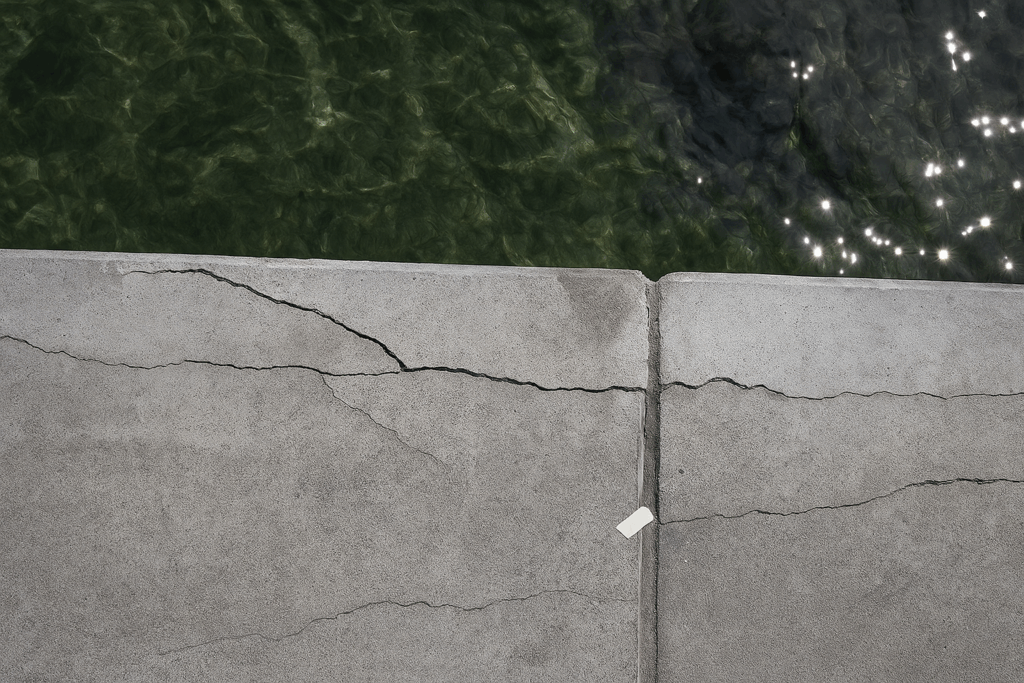

Concrete structures need to be protected in terms of damages occurring because of various chemical reactions and water leakage. Existing structures should be protected from leakage/corrosion due to water seepage and environmental damages. New structures should be designed for long-term performance using various methods of protection.

Curing of Concrete

In all but the least critical applications, care needs to be taken to properly cure concrete to achieve best strength and hardness. This happens after the concrete has been placed. Cement requires a moist, controlled environment to gain strength and harden fully. The cement paste hardens over time, initially setting and becoming rigid though very weak, and gaining in strength in the weeks following. In around 3 weeks, typically over 90% of the final strength is reached, though strengthening may continue for decades. The conversion of calcium hydroxide in the concrete into calcium carbonate from absorption of CO₂ over several decades further strengthens the concrete and makes it more resilient to damage. However, this reaction, called carbonation, lowers the pH of the cement pore solution and can cause the reinforcement bars to corrode.

Hydration and hardening of concrete during the first three days is critical. Abnormally fast drying and shrinkage due to factors such as evaporation from wind during placement may lead to increased tensile stresses at a time when it has not yet gained sufficient strength, resulting in greater shrinkage cracking. The early strength of the concrete can be increased if it is kept damp during the curing process. Minimizing stresses prior to curing minimizes cracking. High-early-strength concrete is designed for fast-track construction, where a type of cement that increases shrinkage and cracking. Strength of concrete changes (increases) up to three years. It depends on cross-section dimension of elements and combinations of structural concrete.

During this period concrete needs to be kept under controlled temperature and humid atmosphere. In most cases, this is achieved by spraying or hosing the concrete surface with water, thereby protecting it from the medium ill effects of ambient conditions. The pictures to the right show two of many ways to achieve this, providing a submerging setting concrete in water, then wrapping in plastic to contain the water in them.

Properly curing concrete leads to increased strength and lower permeability, and avoids cracking and chipping due to post reactivity. Care must also be taken to avoid freezing, or overheating the concrete during winter (the Hoover Dam site used to carry coolant during setting to avoid damaging overheating). Improper curing can cause skin scaling, loss of surface, poor abrasion resistance, and cracking.

The figure shows case of concrete spalling caused after the steel starts rusting. This is observed more in coastal area which is affected by the behavior the carbonation of the concrete and steel corrosion.

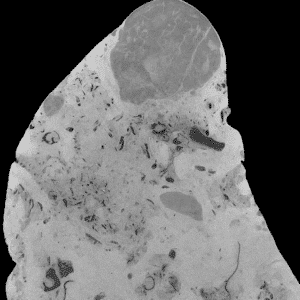

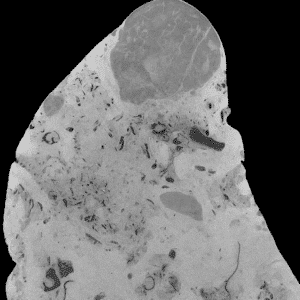

Years of salt water exposure have dissolved calcium-based fillers (damp and snail shells), leaving air voids. Concrete can be damaged by many processes, such as the expansion of corrosion products of the steel reinforcement bars, freezing of trapped water, fire or radiant heat, aggregate expansion, sea water effects, bacterial corrosion, leaching, erosion by fast-flowing water, physical damage and chemical damage (from carbonation, chlorides, sulphates and distillate water).

Concrete can be damaged by many processes, such as the expansion of corrosion products of the steel reinforcement bars, freezing of trapped water, fire or radiant heat, aggregate expansion, sea water effects, bacterial corrosion, leaching, erosion by fast-flowing water, physical damage and chemical damage (from carbonation, chlorides, sulphates and distillate water).

Repair techniques

The first step should always be an investigation to determine the cause of concrete deterioration. The general approach to repairs must: avoid or prevent further degradation; retain expected steel performance; and upgrade the durability and strength of damaged concrete.

Several techniques are available for repairing concrete. It is important to select the appropriate technique depending on the cause of damage as well as the end result expected. Coatings (chemical attack, fire) and waterproofing are used to fully seal and protect the entire surface. Minor repairs are typically done using polymer-based products. RW, a ready to use flexible mortar, Multicrete CM and Multicon MC are commonly used in dry sites. Multichem products are widely used by major companies in India.

Techniques for arresting and preventing further degradation include Cathodic protection; Chloride extraction; Re-alkalization; repair of cracks and surface coatings. For anti-carbonation, Multicon Anticab works as a long protection. Even coatings such as Multicoat MT are designed to protect steel from corrosion, when exposed to moisture and CO₂.

In case the steel is corroded, the repair of cracks is to use bacteria. BacillaFilla is a genetically modified bacteria capable of growing inside damaged concrete, filling in the cracks, and making them whole again.

Techniques for filling holes and cracks include: removal of spalled or damaged concrete and hole-filling repair such as RM flow, flowing concrete repairs; such as Multicon, (epoxy coat and cement neo-concrete products are sprayed concrete repairs). For exposed steel, a corrosion protection coating such as Rustoxil works on long-term protection of steel in the structure.

Strengthening techniques

While techniques are available for increasing the load-carrying capacity, increase in thickness and weight can also be avoided. To avoid shrinkage in concrete cross-sections, adding stiffeners, or reducing the distance between supports, and providing additional ties is also used. Techniques such as steel jacketing or steel braces, or using Fibre Wrap System are successful for repairing cracks or strengthening the structure.

Requirement of Waterproofing of Structure

High economic losses:

- Expenses for repairing infrastructure in US estimated to be 10% of their construction cost.

- Indirect losses due to traffic delay

- For repairing bridges, 10 times higher than repair cost

- Expenses for repairing the whole deteriorated/damaged infrastructures in Canada estimated to be ~ $500 B

- One third of bridges in the U.K. necessary to be repaired

- Losses per year due to the corrosion of civil construction facilities in developed countries estimated to be 1.5–2% GDP, mainly due to the corrosion of concrete

- In 2008, GDP of China achieved ~ $460 B, but the loss per year due to corrosion reached ~ $14 B

Root cause

Permeation of water, air and other aggressive harmful agents!

Water seepage inside the structure through cracks or capillaries/porosity leads to corrosion of reinforcement and carbonation of concrete as mentioned above.

Hence, waterproofing of concrete structures becomes a key activity to protect concrete and enhance the service life.

There are two types of waterproofing systems available in the market.

- Membrane Waterproofing

Under this category, Multichem manufactures Leakshield, Multiguard A, Roofshield, Rainshield and many products as per the structure.

These products form membranes which arrest water seepage inside the concrete structures.

- Waterproofing by Crystallization / In-depth Waterproofing

Under this category, products are either surface applied or added into the concrete. Multiguard In-depth range of products are based on crystallization technology and give rise to permanent waterproofing/protection.

In-depth waterproofing products are integral waterproofing products which are added to the green concrete during construction. Such products are Multiguard IW+ and Eagle Leak-Lock.

Summary

Nowadays, it has become necessary that concrete is protected from damaging chemicals and water. If deterioration has taken place, we should repair the structure with a proper concrete repair scheme. Waterproofing, if carried out properly, will keep the structure away from deterioration. Right products and schemes are key parameters to get the best results.

For further details contact:

Multichem Industries Pvt. Ltd.

Phone No: +91 9619091025

E-mail: info@multichemgroup.net

Web: www.multichemgroup.net

Concrete can be damaged by many processes, such as the expansion of corrosion products of the steel reinforcement bars, freezing of trapped water, fire or radiant heat, aggregate expansion, sea water effects, bacterial corrosion, leaching, erosion by fast-flowing water, physical damage and chemical damage (from carbonation, chlorides, sulphates and distillate water).

Concrete can be damaged by many processes, such as the expansion of corrosion products of the steel reinforcement bars, freezing of trapped water, fire or radiant heat, aggregate expansion, sea water effects, bacterial corrosion, leaching, erosion by fast-flowing water, physical damage and chemical damage (from carbonation, chlorides, sulphates and distillate water).