It has been reported that heavy rains and a burst geyser or water pipe are one of the most damaging disasters to a building. Waterproofing a building plays a pivotal role in preventative risk management. It is cheaper to outlay money before damage is caused as opposed to outlaying money after damage has been caused.

The waterproofing should be made mandatory for all structures and should not be an optional one. The approach to waterproofing problems must be conceptual and the selection of appropriate material and proper diagnosis of the problem and employing the right applicator for executing the job is equally important.

Waterproofing is as important as any other parameter involved in designing a structure. It is because waterproofing also plays a vital role towards the durability of concrete as well as the safety of the structure.

Waterproofing Methods

Water is the most destructive weathering element of concrete structures; water continues to damage or completely destroy more buildings and structures than natural disasters. Waterproofing techniques preserve a structure’s integrity and usefulness through an understanding of natural forces and their effects during its life cycle.

What is Waterproofing?

“It is the formation of an internal or external membrane which is designed to prevent water from entering or escaping the concrete. Internal membranes are created with waterproofing admixture. External membranes are applied to the surface of the concrete—nearly always on the positive side.

External membrane is divided into two subcategories: fluid-applied membranes and sheet-applied membranes. There are a few types of the most commonly used systems of waterproofing in the construction industry:

• Cementitious waterproofing

• Liquid waterproofing membrane

• Bituminous coating

• Bituminous membrane

• Polyurethane liquid membrane

Cementitious waterproofing:

Cementitious waterproofing is often used in internal wet areas such as toilets. Most of the time, the type of cementitious waterproofing is semi-flexible, some even toward rigid type. It is still good to use because internal toilets are not exposed to sunlight and weathering, and so they do not go through the contraction and expansion process continuously.

Liquid waterproofing membrane:

Liquid membrane is a thin coating which consists of usually a primer coat and two coats of top coats. It offers more flexibility than the cementitious types of waterproofing. The elongation properties of the coating can reach as high as 1000%. But the durability of the waterproofing coating also depends on what type of polymer the manufacturer uses for making the liquid waterproofing.

Bituminous coating:

Bituminous waterproofing coating is made of bitumen-based materials and is not suitable for exposure to sunlight. It becomes very brittle and fragile when long exposure to the sunlight unless it is modified with more flexible material such as polyurethane or acrylic-based polymers. The flexibility of the finished products always depends on the solid content of the polymer added to the bitumen.

Bituminous Membrane:

Bituminous waterproofing membranes include torch-on membranes and self-adhesive membranes. Torch-on membrane is the more preferred one because of its shelf life and ease of use during application.

The self-adhesive type must be used quickly, as the bonding properties of the membrane reduce over time. Very often, applicators find the self-adhesive membrane has already lost its bonding properties when they are ready to apply it. Therefore, they have to use an additional primer to prevent debonding issues in the near future.

Torch-on membranes come in exposed and covered types. Exposed membranes often have mineral granular aggregate to withstand weathering and wear. For the other type of membrane, contractors need to apply a protective screed to prevent puncture of the membrane.

However, one has to be very careful when applying the protective screed, which is often cement mortar. The cement ratio has to be high, and the mixing must be thorough throughout the process. There is premixed cement mortar available in the market for better quality and consistency. Site mix usually compromises the quality of the finished work, but the cost is always cheaper compared to premixed mortar.

Polyurethane Liquid Membrane:

Polyurethane is also used for flat roof areas exposed to weathering, though it is expensive. It offers higher flexibility. Polyurethane is very sensitive to the moisture content present; therefore, before application, one must carefully evaluate the moisture content of the concrete slab. Otherwise, peeling or debonding can easily be observed after some time.

Waterproofing Technology: Hydrophilic vs. Hydrophobic Hydrophobic or water-repellent products repel water by increasing hydrophobicity. They reduce water absorption but are not sufficient to resist significant water pressure.

Hydrophobic or water-repellent products repel water by increasing hydrophobicity. They reduce water absorption but are not sufficient to resist significant water pressure.

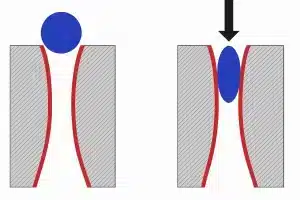

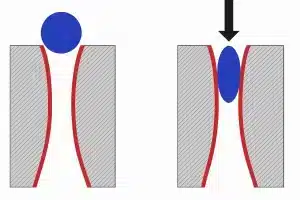

Hydrophilic chemicals absorb and utilize water to catalyze and react with cement particles to produce elongated crystalline structures. They physically block pores, cracks, and the interfacial transition zone (ITZ) to sufficiently resist the penetration of water under pressure. Such types of waterproofing products are commonly called catalytic waterproofing by crystallization, e.g., Hydronil range of products, manufactured by Multichem.

Positive and Negative-side Waterproofing

Positive and Negative-side Waterproofing

Positive-side waterproofing: When referring to the positive side of waterproofing application, we are talking about the side where the water will be coming in contact with the concrete. The opportunity to waterproof the positive side is mostly there only during construction.

Negative-side Waterproofing:

Negative-side waterproofing is applied to the inside (dry) face of a structure (or the outside of a reservoir). Easy access to the dry side makes negative-side waterproofing the first choice for remedial projects.

Multichem Group Provides You Advanced Waterproofing Coatings

MULTIGUARD IW+ – An Integral Waterproofing Product

It is always better to add waterproofing additives to fresh/green concrete and plaster before they are cast or applied. Such additives provide excellent waterproofing properties inside the body of the mass by creating a cohesive mix and internal waterproofing barrier. These additives are called integral waterproofing compounds. Multiguard IW+ falls into this category and imparts corrosion protection to rebars along with leakage protection.

LeakShield

LeakShield is a single-component, polymer-modified, cementitious high-performance waterproofing coating for concrete protection. LeakShield forms a dense, waterproof surface barrier. It consists of Portland cement, well-graded quartz sand, and active polymer-enhanced special chemical ingredients (with nanotechnology), forming a hard and flexible membrane.

It consists of Portland cement, well-graded quartz sand, and active polymer-enhanced special chemical ingredients (with nanotechnology), forming a hard and flexible membrane.

LeakShield can be used for rigid waterproofing of water tanks, sealing internal basement and cellar walls against dampness and water leakage, and protecting concrete structures in marine environments. It is also suitable for external tanking of substructure concrete such as foundations and basement walls in new buildings. The product can withstand positive-side water pressure up to 8 bar (atm). For terrace or exterior waterproofing protection, the product is available in white, gray, and multiple colors.

Hydronil – Waterproofing of Concrete Structure by Catalytic Crystallization

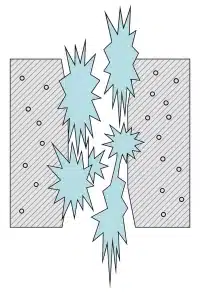

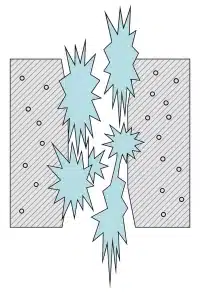

Waterproofing of rigid structures such as basements, water tanks, and swimming pools can be best achieved by catalytic crystallization-based waterproofing products. The Hydronil range of products provides near-permanent protection for the lifetime of a structure. These products become part of the concrete mass itself, leaving virtually no chance of damage from external factors. Structures waterproofed with Hydronil products can withstand up to 17 atm water head.

RainSheild – Elastomeric Waterproofing Coating

RainSheild is a water-based, high-solid elastomeric coating that utilizes the latest advances in acrylic and polyurethane technology. High-quality resins are combined with reinforcing laminar pigments, effective biocide packages, and non-migrating fire retardants, resulting in:

• Superior durability

• Weatherproofing

• Ultraviolet resistance

• Algae and mildew resistance

• Fire retardancy

RainSheild is highly reflective, thermally insulating, and forms a permanently flexible, breathable membrane. It allows moisture vapor from the substrate or building interior to escape while preventing mass water penetration from the exterior.

Unique Features of RainSheild:

• Superior flexibility, hardness, and solvent resistance

• Bridges substrate cracks up to 2 mm

• Long-term crack resistance

• Superior freeze/thaw resistance

• Self-curing

• Very low shrinkage

• Non-toxic and environmentally friendly

• Anti-fungal and anti-algae properties

• Exceptional exterior durability and UV resistance

• High-temperature stability

• Low-temperature flexibility down to –15˚C

• Dirt pick-up resistance

• Excellent adhesion to polyurethane foam and many other substrates

• High reflectivity that reduces wall surface temperatures, thereby prolonging wall life and lowering interior temperatures

• Easy application by spray, brush, or roller—reducing application costs

• Low toxicity and odor

• Simple water cleanup for manufacturers and contractors.

ROOFSHIELD: Elastomeric Waterproofing Coating

ROOFSHIELD is a water-based high-solid elastomeric coating utilizing the latest advances in acrylic and polyurethane technology. Highest quality resins are combined with reinforcing laminar pigments, an effective biocide package, and non-migrating fire retardant, resulting in superior durability, weatherproofing, ultraviolet resistance, algae/mildew resistance, and fire retardancy. Roofshield® is highly reflective, thermal insulating, permanently flexible, and forms a breathing membrane, allowing moisture vapor from the substrate or building interior to escape while remaining impervious to mass water penetration from the exterior. It is available in high tensile strength version for roof areas subject to heavy maintenance traffic, severe weather conditions, chemical fallout etc.

Uses:

- Cured concrete substrate (Flat or sloping)

- All metal roofs

- Polyurethane foam, Asphalt shingles, EPDM, Hypalon, bitumen etc.

- Wood

- Old buildings

Conclusion:

Waterproofing of structure is as important as any other construction related activities of the project. In fact, waterproofing will make structure more durable and long lasting. It is also equally important that different products should be chosen as per the waterproofing requirement, e.g. Basement is best protected by crystalline based technology and roofs are protected from water and heat by using elastomeric coatings. These coatings can last for more than 15 years.

For further details contact:

Multichem Industries Pvt. Ltd.

Phone No: +91 9619091025

E-mail: info@multichemgroup.net

Web: www.multichemgroup.net

Hydrophobic or water-repellent products repel water by increasing hydrophobicity. They reduce water absorption but are not sufficient to resist significant water pressure.

Hydrophobic or water-repellent products repel water by increasing hydrophobicity. They reduce water absorption but are not sufficient to resist significant water pressure. Positive and Negative-side Waterproofing

Positive and Negative-side Waterproofing

It consists of Portland cement, well-graded quartz sand, and active polymer-enhanced special chemical ingredients (with nanotechnology), forming a hard and flexible membrane.

It consists of Portland cement, well-graded quartz sand, and active polymer-enhanced special chemical ingredients (with nanotechnology), forming a hard and flexible membrane.